AXLES

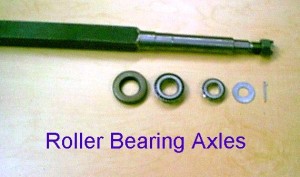

ROLLER BEARING AXLES

Most new vehicles are equipped with roller bearing axles as shown here. An advantage in roller bearing axles is less frequent maintenance and adaptability to hydraulic brakes.

These come in sizes from 1” to 2½” as measured at the square portion of the axle and are often referred to as ‘standard track’ and ‘wide track’. The standard track will measure about 48” between spindles and the wide track will measure close to 54”. Overall lengths are available up to 75” by special order.

1” and 1 1/8” are common to most light vehicles such as doctor’s buggies and phaetons. The surreys, spring wagons and Vis-à-vis will have the 1¼” sizes. Vehicles which accommodate more passengers, such as wagonettes, ought to be up to 1½” size. When you go into the light coaches the 1¾” axle is appropriate, while the larger coaches, drays and freighters will require the larger 2” to 2½” axles.

THESE ARE SPECIAL ORDER BECAUSE OF THE MANY VARIATIONS IN LENGTH AND BEND , SO PLEASE CONTACT US BY PHONE OR EMAIL.

ROLLER BEARING STUBS

BOXING STYLE AXLES

Pictured here is the boxing style axle commonly found on older original vehicles produced here in the United States. Measurements and functionality is the same as the roller bearing axles, but the draw back is the routine maintenance required. Since both ends of the boxing are open and exposed, the grease tends to work its way out and needs to be regularly replenished. Because of the inner collar between the spindle and the square body of the axle, this style axle is not easily fitted to hydraulic brakes. The collar will not allow a backing plate to be installed which is necessary with drum style brakes.

THESE ARE SPECIAL ORDER BECAUSE OF THE MANY VARIATIONS IN LENGTH AND BEND, SO PLEASE CONTACT US BY PHONE OR EMAIL.

Often the question is, “When is it beneficial to change from old style to roller bearing style axles?”

When originality is not the issue and maintenance is a concern, roller bearing axles are something to consider. When a roller bearing axle conversion is considered, one must also realize that different wheels with hubs that accommodate these axles will be required. (Since the Timken bearing did originate in the buggy era, there are a few originals out there, but not real common. Some of the heavy tanker wagons also came equipped with ball bearings.)

Question; “Does a buggy or wagon pull easier with roller bearing axles?”

You will not notice a difference in how a vehicle pulls until you get into the larger class vehicles. An old style axle, when greased properly, will pull quite easily. The draw back here is the routine maintenance to keep these axles greased properly.

Question; “Can I just cut off my old spindles and weld on new roller bearing spindles?”

Spindles are less expensive than full length axles; however there are additional welding expenses and time involved in gauging the axles again for gather and swing (caster and camber). If you are doing this conversion yourself and time is not the issue, then you will have less expense. But if you have to hire a welder to help you, the full length axles will be less expensive in the end.

ROLLER BEARING BOXINGS

Another option for larger worn out axles is to replace the axle with roller bearing and also place a roller bearing boxing into the old hubs. There are limitations to this approach, especially in light vehicles. Because the roller bearing boxing is machined to accommodate bearings, it is significantly larger than many small boxings and hub size limitations will not allow its insertion. As a general rule, a wheel has to have 1¼” spoke or larger to have a hub large enough for this approach.

Here in the west we see a large number of farm wagons, chuck wagons, sheep wagons, etc. that have worn out axles, or gears with no wheels because someone has put them in a flower garden. Shown here is an approach of insetting a 2” roller bearing axle up into the old wooden axle thereby making a useless gear usable again, keeping an authentic look.

Whatever your axle problems are, there is usually an answer to it. If we can help you out, we’d be happy to.

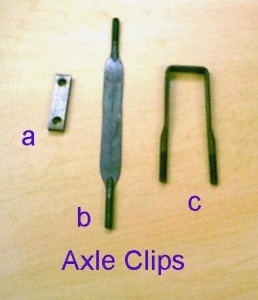

AXLE CLIPS

Axle clips fasten wood axle caps to the steel axles and come in every ½” in lengths starting at 2½” up to 7”. This measurement is the portion of the clip that is flat and does not include the threaded ends. Picture “a” is the clip bars that goes under the axle which the axle clips and spring clips “c” are fastened to. These clips are threaded with 5/16” threads and include square nuts. The spring clips “c” are half-round between the threads. I have some pre-bent for 1½” or 1¼” springs and also straight, which can be shaped to any size.

AXLE CLIPS

AXLE CLIP BARS